Handling instructions

To use SubConn underwater connectors correctly, please follow the handling instructions below:

- Be sure to grease the connector before connecting it.

- When disconnecting the connector, pull it straight out without bending it.

- Do not bend sharply or pull hard when connecting or disconnecting the cable.

- When using bulkhead connectors, do not apply a load in the perpendicular direction.

- When tightening the bulkhead nut, be sure to apply the recommended torque.

- Do not expose the connector to heat or direct sunlight for a long time.

- If it should dry out, soak it in fresh water before use.

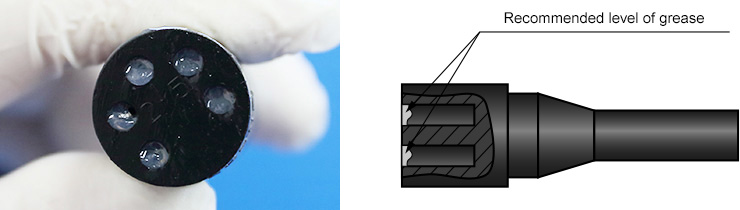

Greasing procedure for land-based connection

- Before connecting, be sure to apply grease (MOLYKOTE 44 Medium) to the connector.

- To the female connector, apply grease to at least 1/10 of the depth of the socket.

- Grease adequately enough to make sure that the inside of all sockets is fully covered with grease and that there is a transparent layer of grease on the connector surface.

- After applying the grease, check to see if the pins and sockets are optimally greased before connecting the male and female connectors.

- To ensure that the grease is adequately applied, disconnect the connection and check that all the male pins are greased. Then reconnect the connector.

Greasing procedure for underwater connection

- Before connecting, be sure to apply grease (MOLYKOTE 44 Medium) to the connector.

- To the female connector, apply grease to about 1/3 of the depth of the socket.

- Grease adequately enough to make sure that all sockets are completely sealed and that there is a transparent layer of grease on the connector surface.

- After applying the grease, remove the grease from areas other than the connector connection area and connect the male and female connectors.

Cleaning

- When generally cleaning or removing sand and mud adhering to the connector, use a contact cleaning agent (isopropyl alcohol) spray.

- When connecting, apply fresh grease again.

Use of Loctite

- Use “Loctite 5910” to fix non-metallic (resin) connectors.

- “Loctite 243” is recommended for metal connectors.